Executive Summary

Supplier and Material Quality Analysis is critical for the semiconductor industry to ensure consistent, high-quality inputs that drive yield and reliability. Leveraging NexaStack’s agentic infrastructure, including Vision AI for real-time defect detection and Physical AI for automated material handling, enterprises can achieve precision validation and inspection workflows.

The unified analytics platform integrates data from suppliers, MES, and ERP systems to provide seamless supplier evaluation and compliance tracking. Edge AI capabilities enable on-device intelligence for low-latency monitoring, while digital twin models simulate material and supply chain scenarios for proactive risk mitigation. Agentic AI agents continuously monitor supplier performance, enabling automated alerts and decision-making to reduce defects and optimize sourcing. This approach delivers enhanced traceability, faster onboarding, and improved manufacturing outcomes, positioning semiconductor manufacturers for future-ready supply chain excellence.

Business Challenges

- Variations in supplier material composition affect wafer fabrication and chip performance.

- Manual inspections are slow, prone to error, and costly.

- Limited correlation between supplier performance and production outcomes.

- Increasing regulatory expectations for traceability and documentation.

- Legacy integration issues with suppliers, logistics, and MES systems.

Technical Challenges

-

Diverse material properties requiring adaptive inspection methods (silicon, metals, chemicals).

-

Data silos from suppliers, laboratories, and production equipment.

-

Need for real-time anomaly and defect detection.

-

Scalability limitations arise from the manual assessment of large volumes of suppliers.

-

Security risks around proprietary formulas and supplier contracts.

Security and Compliance

-

Secure, unified audit trails for supplier-related decisions and inspections.

-

Role-based access management and encrypted documentation.

-

Automated compliance reports for ISO, JEDEC, and customer standards

Solution Overview

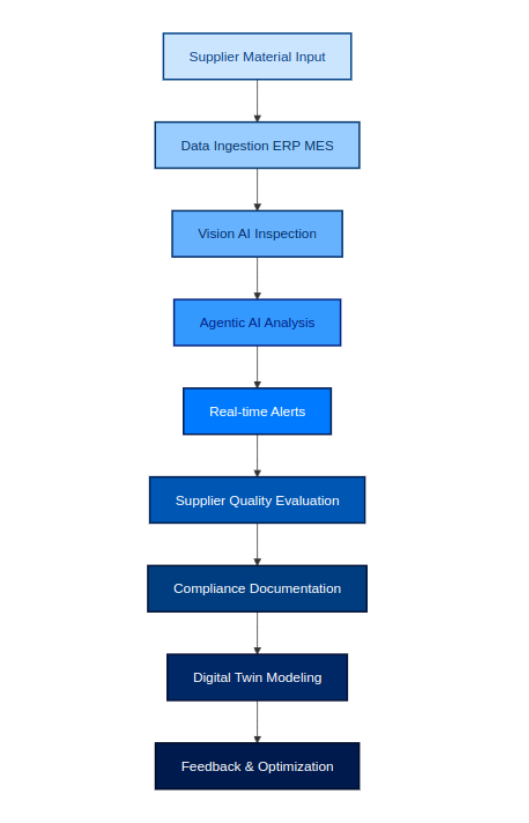

Implement NexaStack Vision AI and Physical AI for automated visual inspection and robotics-driven material handling. Employ AgentAnalyst.ai and AgentSRE.ai for continuous supplier evaluation, anomaly detection, and optimization recommendations. Integrate unified analytics platforms to correlate supplier quality with yield, defect rates, and production cycle times. Leverage digital twin models for simulation and risk forecasting

Targeted Industries

-

Semiconductor manufacturing (wafer fabrication, photolithography, packaging).

-

Electronics assembly and high-precision equipment production.

Recommended Agents

-

Agent Analyst: Correlates historical supplier-quality data and forecasts material quality risk.

-

Agent SRE: Monitors batches, detects non-compliance, and triggers alerts.

-

Vision AI Agents: Automated defect detection and grading.

-

Physical AI Agents: Robotics for sorting and material handling

Solution Approach

-

Ingest supplier, logistics, and production data from ERP, MES, and SCADA systems.

-

Use digital twin simulations to identify supplier and material bottlenecks.

-

Utilize Vision AI for real-time defect detection and automated feedback to suppliers.

-

Utilize agentic workflows for supplier rating and adaptive sourcing decisions.

Fig 1: High-Level Architecture

Fig 1: High-Level Architecture Impact Areas

-

35% reduction in inspection and onboarding cycle times.

-

28% yield improvement from material quality-driven process optimization.

-

42% decrease in defect rates via predictive supplier evaluation and AI analytics.

-

Enhanced traceability and compliance through automated documentation.

Results and Benefits

-

Faster time-to-market through optimized supplier management.

-

Improved consistency and reliability of semiconductor products.

-

Reduced manual inspection costs via automation.

-

Scalable implementation across multiple fab sites

Lessons Learned

-

Unified, clean data streams are essential for actionable quality insights.

-

AI agent recommendations should be guided by domain expertise.

-

Focus initial efforts on high-impact suppliers to achieve quick wins.

-

Continuous feedback and documentation promote adoption and trust.

Best Practices Identified

-

Gradual rollout of automated inspection and evaluation workflows.

-

Document material quality decisions for audit purposes.

-

Maintain human oversight on critical supplier sourcing and de-listing.

-

Validate AI agent recommendations regularly through testing

-

Expand AI-driven supplier analysis globally across sourcing networks.

-

Integrate multi-variable digital twin models for advanced risk prediction and analysis.

-

Optimize sustainability through analytics of waste and material usage.

-

Progress toward autonomous sourcing decisions based on AI insights

Conclusion

The semiconductor industry's supplier and material quality analysis requires next-generation agentic and AI-driven solutions for consistency, traceability, and scalability. With NexaStack’s Vision AI, Physical AI, and unified analytics infrastructure, manufacturers achieve higher yields, faster cycles, and fully auditable supplier quality management—building a foundation for competitive advantage and innovation.

FAQ — Supplier & Material Quality Analysis

Supplier & Material Quality Analysis with Nexastack enables enterprises to ensure consistent quality across their supply chain.

What is Supplier and Material Quality Analysis?

It is the evaluation of supplier performance and material quality using data insights for better reliability.

How does Nexastack improve this process?

Nexastack automates data collection, detects quality issues, and delivers real-time performance insights.

What are the main benefits?

It improves visibility, reduces defects, ensures compliance, and enhances sourcing decisions.

Can it integrate with ERP or PLM systems?

Yes, it connects with ERP, PLM, and MES systems for seamless quality data management.

How does AI support supplier risk management?

AI identifies non-compliance trends, predicts risks, and recommends reliable alternatives.