Customer Challenge

Business Challenges

The customer, a global car manufacturer, struggled with the following issues:

-

Data Security Concerns: Robotic AI workloads processed sensitive production data, which could not leave the factory.

-

Compliance Pressure: Needed to meet strict data residency and privacy regulations.

-

Operational Inefficiency: Manual monitoring and optimization of robot paths slowed production and limited throughput.

Business Goals:

-

Deploy AI workloads securely within private cloud infrastructure.

-

Ensure compliance with industry regulations and internal policies.

-

Increase operational efficiency through intelligent automation of robotic workflows.

Existing Solution Limitations:

-

Legacy on-premises systems lacked AI optimization capabilities.

-

Public cloud solutions raised compliance and data privacy concerns.

-

Manual scheduling and monitoring led to an inefficient production cycle.

Technical Challenges

Infrastructure and System Issues

-

On-premises servers were not optimized for AI model training or inference.

-

Lack of integrated orchestration tools for deploying and scaling multiple AI workloads.

-

Data silos from different robot controllers and vision systems limited analytics capabilities.

Integration and Data Management Issues

-

Disparate robotic and sensor protocols created inconsistent data streams.

-

Limited integration with MES (Manufacturing Execution Systems) and ERP for workflow automation.

Security and Compliance

-

Public cloud usage could expose sensitive production and intellectual property data.

-

No centralized audit trail for AI decision-making processes.

Partner Solution

Solution Overview

The manufacturer implemented NexaStack AI Private Cloud, creating a secure, scalable AI infrastructure for robotic workloads.

-

Agent SRE: Monitors real-time robot telemetry, detects anomalies, and flags suboptimal motion paths.

-

Agent Analyst: Optimizes robot path planning, analyzes vision data for quality assurance, and forecasts maintenance needs.

Together, these agents:

-

Auto-generate alerts for robotic anomalies.

-

Optimize production workflows through predictive modelling.

-

Ensure that all data and model operations remain within the private cloud for compliance purposes.

Targeted Industries:

|

Industry |

Use Cases |

Value Delivered |

|

Automotive & Manufacturing |

Robotic assembly, motion planning |

Improved throughput, reduced downtime, and data security |

|

Industrial Automation |

Production line optimization |

Scalable AI-driven workflow management |

|

Smart Manufacturing |

Vision analytics, predictive maintenance |

Compliance, operational efficiency, and reduced errors |

Solution Approach

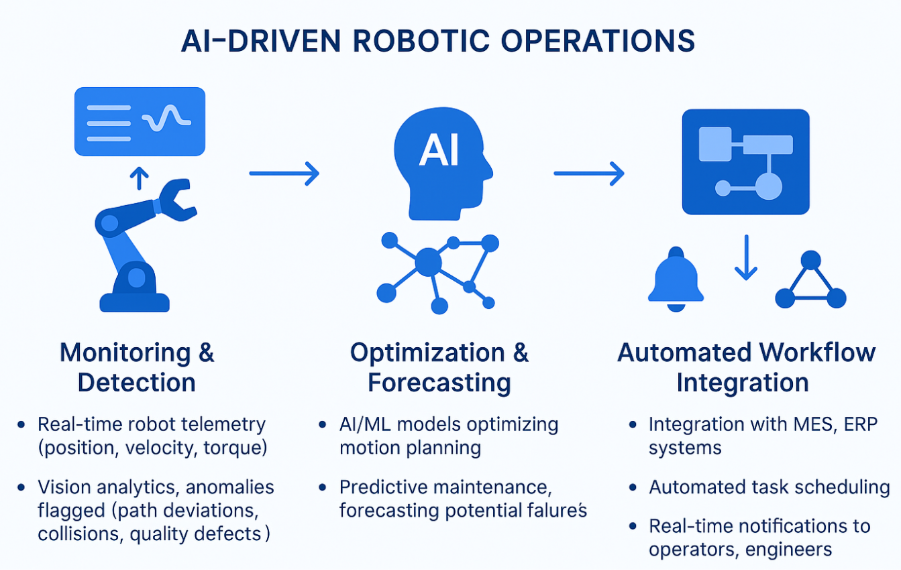

Monitoring & Detection

-

Agent SRE ingests real-time robot telemetry (position, velocity, torque) and vision analytics.

-

Flags anomalies such as path deviations, collisions, or quality defects.

Optimization & Forecasting

-

Agent Analyst uses ML models to optimize motion planning and predictive maintenance scheduling.

-

Forecasts potential maintenance needs before failures impact production.

Automated Workflow Integration

-

Integrates with MES and ERP systems to auto-schedule robot tasks and maintenance.

-

Notifies operators and engineers in real-time of critical actions.

Impact Areas

Model

-

Optimized AI models reduce production errors and improve path efficiency.

-

Feedback loop continuously re-trains models for higher precision.

Data

-

All telemetry and vision data are centralized within a private cloud.

-

Ensures regulatory compliance and full data sovereignty.

Workflow

-

Automated anomaly detection → optimization → execution.

-

Reduced manual interventions, enhanced operational visibility.

Results and Benefits

Business Benefits:

-

Reduced errors and inefficiencies in robotic operations.

-

Faster and more streamlined production cycles.

-

Improved compliance with internal policies and industry regulations.

Technical Benefits:

-

Scalable deployment of AI workloads in a private cloud.

-

Real-time monitoring of hundreds of robotic agents.

-

Secure, auditable infrastructure for sensitive production data.

Customer Testimonial

"NexaStack AI’s Private Cloud solution allowed us to scale our robot AI workloads securely while keeping production data in-house. Our operations are more efficient, compliant, and resilient than ever before."

Lessons Learned

-

Data Security is Critical: Private cloud deployment ensures compliance and builds trust.

-

Integration is Key: Seamless connection to MES and ERP enhances workflow automation.

-

Continuous Model Feedback: Retraining models based on live data improves AI accuracy and reliability.

Best Practices Identified

-

Start with critical production lines before scaling enterprise-wide.

-

Implement Infrastructure as Code (IaC) for standardized deployments.

-

Establish monitoring, metrics, and model drift detection from day one.

-

Secure data pipelines with encryption and role-based access control.

Future Plans

-

Expand Private Cloud AI to additional production lines and factories.

-

Incorporate digital twins for simulation of robot paths and predictive maintenance.

-

Enhance policy compliance and explainability for AI-driven operations.

-

Move toward autonomous, self-optimizing manufacturing workflows.

Conclusion

By implementing NexaStack AI Private Cloud AI, the manufacturer transformed its robotic operations. The solution reduced errors, improved efficiency, ensured compliance, and maintained complete data security—all while providing a scalable AI infrastructure ready for Industry 4.0 and autonomous production workflows.