Customer and Operational Challenges

Traditional chemical hazard detection relies on manual inspections or stationary sensors, creating operational gaps:

-

Personnel are exposed to toxic environments during ground-level inspections.

-

Delayed or incomplete hazard identification leading to escalation risks.

-

Fragmented or inconsistent data capture complicates regulatory compliance and reporting.

-

Manual processes are unable to scale for complex or large industrial facilities.

Business and Technical Pain Points

Despite technological advances, hazard detection workflows still suffer from inefficiency and risk:

-

Slow, non-standardized manual detection procedures increase exposure and response time.

-

Disconnected datasets hinder collaboration among safety officers, regulators, and response teams.

-

Inconsistent or incomplete documentation undermines legal and regulatory defensibility.

-

Limited edge-to-cloud automation reduces scalability and real-time operational awareness.

NexaStack AI-Powered Solution

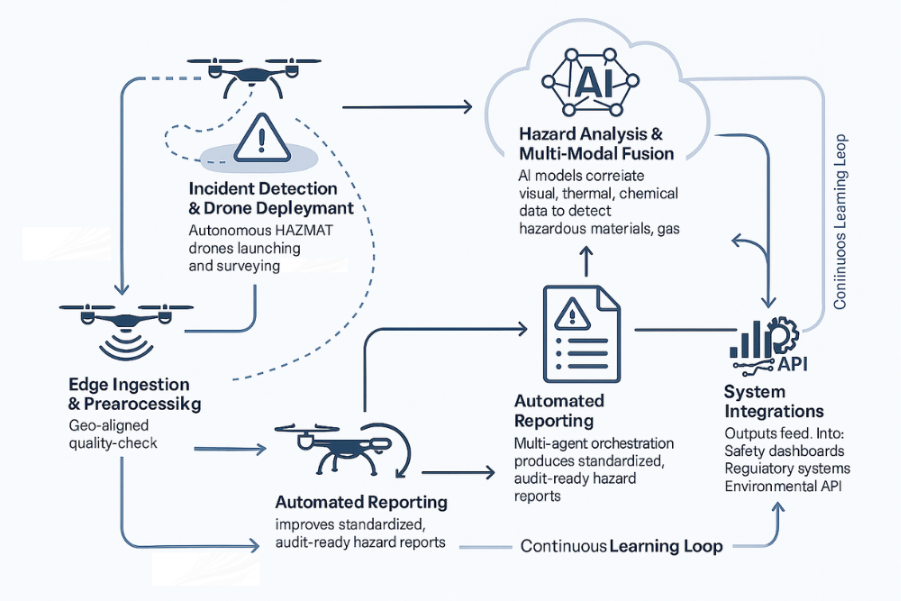

The NexaStack HAZMAT Drone Agent delivers an end-to-end chemical hazard detection workflow. Autonomous drones equipped with gas, thermal, and visual sensors perform pre-mapped and adaptive flight paths, capturing comprehensive multi-modal environmental data.

Data streams are ingested at the edge, where NexaStack nodes handle quality checks, calibration, geo-alignment, and real-time analysis. The AI Reasoning Stack fuses chemical, visual, and thermal inputs, producing accurate contamination maps, leak detection alerts, and predictive risk zones. Multi-agent orchestration automates hazard classification, real-time reporting, and metadata enrichment.

Audit-ready reports embed structured sensor readings, geospatial maps, and encrypted metadata, ensuring regulatory compliance and forensic defensibility. Hybrid cloud-edge architecture enables immediate hazard response while preserving long-term data integrity, security, and organizational control.

Detailed Workflow Description

-

Incident Detection & Drone Deployment (EDGE): Autonomous HAZMAT drones launch to survey the affected area using optimized flight paths.

-

Edge Ingestion & Preprocessing (EDGE): Sensor data streams are processed, geo-aligned, and quality-checked in real time.

-

Hazard Analysis & Multi-Modal Fusion (CLOUD): AI models correlate visual, thermal, and chemical readings to detect hazardous materials, leaks, and gas concentrations.

-

Automated Reporting (CLOUD): Multi-agent orchestration produces standardized, audit-ready hazard reports.

-

Continuous Learning Loop: Incident data feeds back to improve AI model accuracy and predictive capabilities.

-

System Integrations: Outputs integrate with safety dashboards, regulatory systems, and environmental monitoring APIs.

Operational and Business Impact

-

Significantly reduces human exposure to chemical hazards.

-

Accelerates incident detection and response times from hours to minutes.

-

Provides consistent, structured, and auditable hazard documentation for compliance.

-

Supports scalable monitoring across large or complex industrial sites.

-

Multi-sensor drone payloads (chemical, thermal, visual, gas detection).

-

AI-driven multi-modal data fusion and hazard detection.

-

Composable agent framework for autonomous workflow orchestration.

-

Edge compute nodes for low-latency hazard analysis.

-

Secure encryption, role-based access control, and federated governance.

-

API-first integration with industrial and environmental systems.

Why NexaStack Stands Out for This Use Case

-

Agentic AI Architecture: Autonomous, distributed workflows accelerate detection, reporting, and predictive modeling.

-

Edge and Hybrid Cloud Deployment: Low-latency hazard detection in connectivity-limited industrial environments with secure hybrid cloud scalability.

-

Unified AI Reasoning Stack: Multi-modal sensor fusion and automated hazard classification ensure accurate, auditable insights.

-

Sovereign AI Security and Compliance: Granular access control, encryption, and audit trails meet stringent safety and regulatory requirements.

Lessons Learned and Future Directions

-

Standardized flight paths and sensor configurations improve repeatability and operational readiness.

-

Continuous model refinement improves leak detection, gas concentration mapping, and contamination prediction.

-

Future extensions include predictive pre-incident hazard scouting, automated containment coordination, and integration with emergency suppression systems.

Conclusion

NexaStack’s agentic AI-powered HAZMAT Drone Agent and Multi-Modal AI Model redefine industrial hazard detection by combining autonomous data capture, chemical and environmental analysis, and automated, compliant reporting. This secure, scalable, and integrated solution accelerates emergency response, protects personnel, and ensures regulatory compliance — delivering actionable insights to plant operators, responders, and environmental authorities.