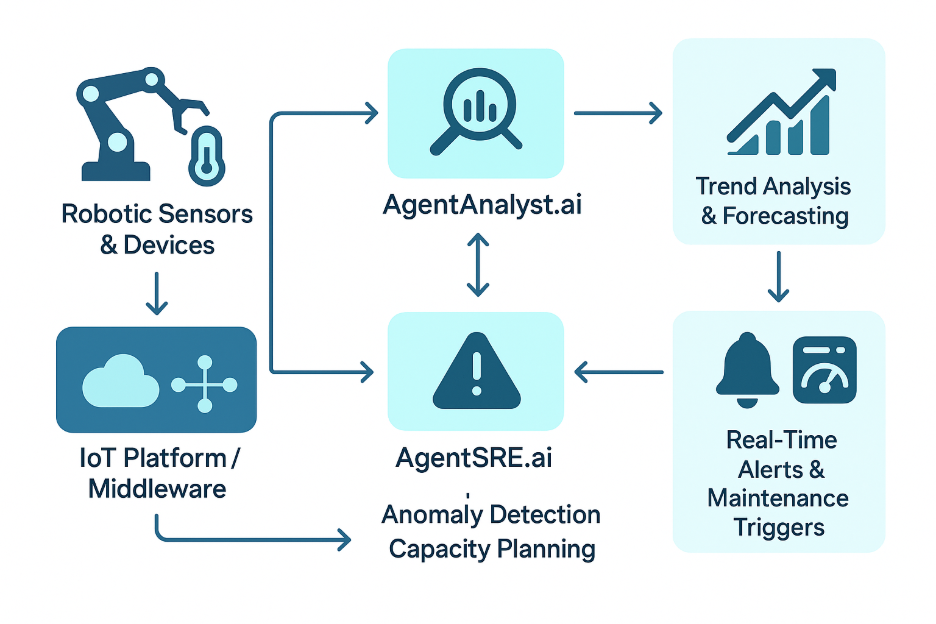

Solution Approach

Real-Time IoT Data Acquisition

-

Stream sensor data (energy, heat, vibration) into the IoT platform.

-

Enable secure communication between robots and monitoring agents.

Predictive Analytics with Agent Analyst

-

Analyze cycle count trends and energy efficiency.

-

Identify patterns of drift before failures occur.

- Issue alerts for overheating, overconsumption, or cycle irregularities.

- Trigger automated workflows to dispatch maintenance teams.

Autonomous Coordination

-

Reallocate workload to healthy robots during downtime.

-

Maintain consistent throughput across welding cells.

Impact Areas

-

Workflow: From reactive repair to predictive, automated maintenance.

-

Data: Unified telemetry data for robots across vendors.

-

Operations: Reduced downtime, optimized cycle efficiency.

Results and Benefits

Business Benefits:

-

30% reduction in downtime from predictive maintenance.

-

25% reduction in energy consumption per cycle.

-

20% extension in the lifespan of robotic components.

-

Improved welding quality and consistency.

Technical Benefits:

-

Real-time IoT telemetry streaming.

-

Automated alerting system integrated with workflows.

-

Scalable, secure architecture for multi-site deployment.

Customer Testimonial

"The IoT platform with AgentAnalyst.ai and AgentSRE.ai has fundamentally changed how we run our robotic assembly line. We no longer wait for failures — the system tells us before they happen."

— Head of Smart Manufacturing, Global Automotive OEM

Lessons Learned

-

Real-time IoT data quality is critical — sensor calibration matters.

-

Integration complexity arises with multi-vendor robotics systems.

-

Cultural change needed: maintenance teams must trust the AI alert

Best Practices Identified

-

Start with a pilot deployment on a single robotic cell.

-

Build a unified IoT data model for robots across vendors.

-

Layer AI-driven predictive insights on top of IoT telemetry.

-

Ensure strong IoT security protocols.

Future Plans

-

Expand IoT monitoring to painting and assembly robots.

-

Develop digital twins of robotic cells for simulation and planning.

-

Integrate sustainability dashboards to measure energy impact.

-

Extend to supply chain robotics for end-to-end visibility and control.

Conclusion

By connecting robotic systems with IoT platforms and agentic AI, the automotive manufacturer achieved a step-change in uptime, energy efficiency, and quality assurance. This IoT-enabled approach ensures predictive, autonomous, and sustainable robotic operations at scale.