In the era of Industry 4.0 and smart manufacturing, maintaining high product quality while optimising efficiency is more critical than ever. Traditional quality control methods—relying on manual inspections or rigid automated systems—are no longer sufficient to meet the demands of high-speed, high-precision production lines.

Enter Agentic AI, a next-generation approach in which autonomous AI agents work collaboratively to monitor, analyse, and optimise real-time assembly line quality. By integrating data from vision systems, IoT sensors, and Manufacturing Execution Systems (MES), these AI agents detect defects as they occur, reduce false alarms, and provide actionable insights to operators, transforming quality assurance from a reactive process into a proactive, self-improving system.

This article explores how Agentic AI-powered real-time detection revolutionises assembly line quality, the challenges it solves, and how manufacturers can implement this technology for maximum impact.

The Growing Importance of Real-Time Quality Control

Manufacturers today face increasing pressure to:

-

Reduce defects to avoid costly recalls and reputational damage.

-

Minimise waste by catching errors before they propagate downstream.

-

Improve efficiency by reducing unnecessary downtime from false alarms.

-

Adapt to variability in materials, machine wear, and environmental conditions.

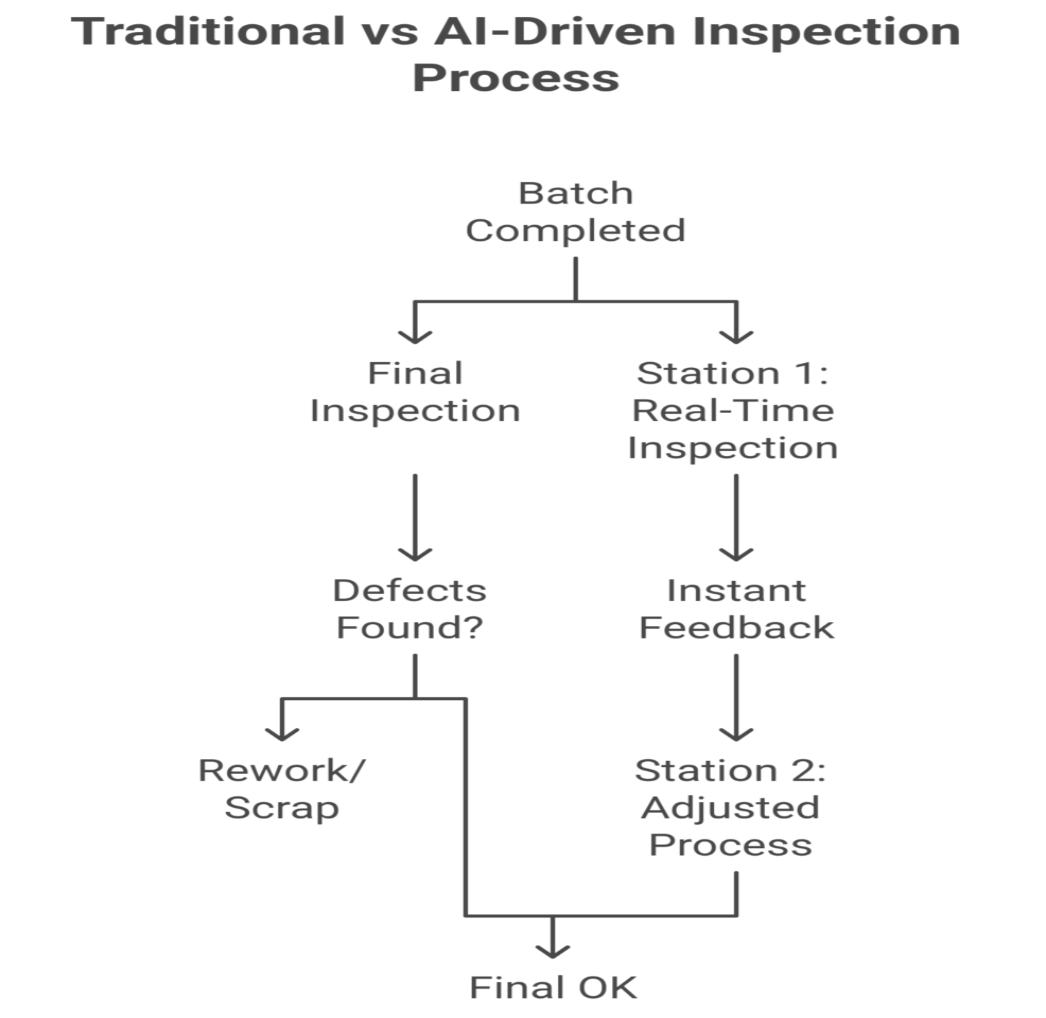

Legacy quality control systems, which rely on sampling-based inspections or rule-based automated checks, struggle with these demands. They are often:

Real-time AI-powered quality control addresses these issues by continuously analyzing production data, learning from trends, and making instant decisions—ensuring defects are caught and corrected at the earliest possible stage.

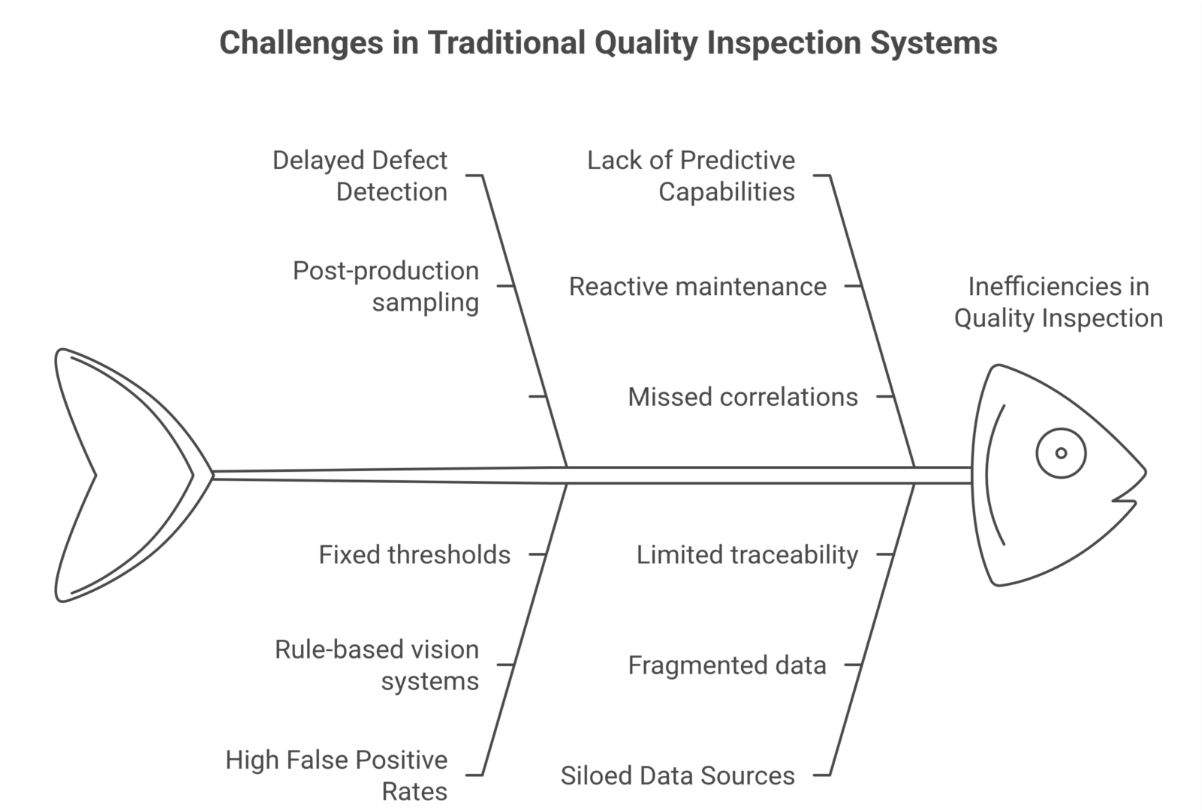

Challenges in Traditional Quality Inspection Systems

While foundational in manufacturing, traditional quality inspection methods suffer from several critical limitations that hinder efficiency, accuracy, and scalability. These challenges become increasingly problematic as production volumes grow and quality standards tighten.

Delayed Defect Detection

Problem:

Most conventional inspection systems rely on post-production sampling or end-of-line checks, meaning defects are only identified after processing an entire batch. By this stage, hundreds or thousands of defective units may have already been produced, leading to significant material waste, rework costs, and delays.

Implications:

-

Increased scrap and rework costs due to late-stage defect discovery.

-

Lost productivity from correcting defects rather than preventing them.

-

Higher risk of defective products reaching customers, damaging brand reputation.

High False Positive Rates

Problem:

Rule-based vision systems (e.g., traditional machine vision with fixed thresholds) struggle to distinguish between actual defects (e.g., cracks, misalignments) and acceptable variations (e.g., harmless texture differences, lighting artefacts). This leads to excessive false alarms, where good products are incorrectly flagged as defective.

Implications:

-

Unnecessary production stoppages reduce Overall Equipment Effectiveness (OEE).

-

Operator fatigue and distrust in the system due to constant false alarms.

-

Increased manual inspection costs as workers second-guess automated decisions.

Lack of Predictive Capabilities

Problem:

Traditional systems focus on detecting defects rather than predicting them. Without AI-powered analytics, manufacturers cannot identify patterns (e.g., tool wear, environmental fluctuations) that precede defects, missing opportunities for proactive intervention.

Implications:

-

Reactive rather than preventive maintenance leads to higher downtime.

-

Missed correlations between process parameters and defect rates.

-

Inability to optimise processes for continuous improvement.

Siloed Data Sources

Problem:

Quality data is often fragmented across vision systems, IoT sensors, and Manufacturing Execution Systems (MES), with no integration. This prevents a holistic view of quality trends and root-cause analysis.

Implications:

-

Inefficient troubleshooting due to disconnected data.

-

Missed opportunities for cross-process optimisation.

-

Limited traceability for compliance and audits.

How Agentic AI Transforms Quality Assurance

Real-Time Anomaly Detection

AI agents process data from high-speed cameras, laser scanners, and spectral sensors in milliseconds, identifying:

-

Dimensional inaccuracies (e.g., out-of-spec tolerances)

-

Surface defects (scratches, dents, discolourations)

-

Assembly errors (missing or misaligned components)

Unlike static algorithms, AI agents continuously learn from new data, improving detection accuracy.

Reducing False Positives with Context-Aware AI

Instead of rigid thresholds, AI agents use multi-sensor correlation to distinguish between:

Real defects (e.g., a cracked component)

Benign variations (e.g., lighting changes, harmless cosmetic marks)

This reduces operator workload and prevents unnecessary production stoppages.

Operator Assistance & Decision Support

When a defect is detected, AI agents don’t just raise an alert—they:

-

Classify severity (critical, minor, or false alarm)

-

Suggest root causes by cross-referencing MES and sensor data

-

Provide repair guidance via augmented reality (AR) overlays or step-by-step instructions

This turns operators into problem solvers rather than just inspectors.

Continuous Improvement via Defect Trend Analysis

By aggregating historical defect data, AI agents help:

-

Identify recurring failure patterns (e.g., a specific machine drift)

-

Predict future defects using predictive analytics

-

Optimise process parameters (e.g., adjusting torque settings to prevent fastener failures)

This creates a self-improving quality loop, where the system gets smarter with every production cycle.

Case Studies: AI in Action

Case Study 1: Delayed Defect Detection in Automotive Manufacturing

Problem:

A major automotive manufacturer faced high scrap rates due to defects (e.g., misaligned welds) detected only at the end of the assembly line. By then, 10-15% of units required rework, costing $500K/month in wasted materials and downtime.

Solution:

-

Deployed AI-powered inline vision systems to inspect welds in real time at each station.

-

Integrated automated feedback loops to adjust welding robots instantly if misalignment is detected.

Impact:

-

↓ 90% scrap/rework (defects caught early).

-

↑ 20% production throughput (fewer line stoppages).

-

$4M/year saved in material costs.

Case Study 2: Reducing False Positives in Pharmaceutical Packaging

Problem:

A pharma company’s rule-based vision system falsely rejected 25% of good blister packs due to minor colour variations, requiring manual checks and slowing output by 30%.

Solution:

-

Replaced rule-based checks with deep learning algorithms to distinguish critical defects from cosmetic variations.

-

Implemented adaptive thresholds based on historical data.

Impact:

-

↓ 80% false positives (only actual defects flagged).

-

↑ 25% line speed (fewer unnecessary stoppages).

-

Saved 200+ hours/month of manual verification.

Implementation Roadmap for Manufacturers

Step 1: Assess Current Quality Systems

-

Identify pain points (false alarms, delayed detection, etc.).

-

Audit existing sensors, cameras, and MES data streams.

Step 2: Pilot AI on High-Impact Lines

-

Start with a critical production line where defects are costly.

-

Deploy AI agents to validate detection accuracy.

Step 3: Scale Across the Factory

-

Integrate AI with ERP/MES for full traceability.

-

Train operators on AI-assisted decision-making.

Step 4: Continuous Optimisation

-

Use AI-generated insights to refine processes.

-

Expand into predictive maintenance and supply chain quality.

Future Trends in AI-Driven Quality Control

Generative AI for Synthetic Defect Training – Simulating rare defects to improve AI detection.

-

Edge AI for Instant Decision-Making – Moving processing to factory-floor devices for ultra-low latency.

-

Self-Healing Production Lines – AI agents that auto-adjust machines to prevent defects.

Conclusion

The transition from reactive, rule-based inspections to AI-driven real-time quality control marks a pivotal shift in modern manufacturing—one that is no longer optional but a strategic imperative for staying competitive. By leveraging agentic AI, manufacturers can detect defects instantly through adaptive learning, minimise false alarms with contextual intelligence, and empower operators with actionable, data-driven insights. Beyond immediate gains, these systems enable continuous improvement via predictive analytics, uncovering hidden patterns to prevent defects before they occur.

Companies that embrace this transformation today will achieve higher efficiency and cost savings and set new benchmarks in product quality and operational excellence. In the rapidly evolving Industry 4.0 landscape, early adopters of AI-powered quality systems will secure a dominant market position, turning quality control from a cost centre into a competitive advantage.

Key Takeaways:

-

Proactive > Reactive: AI shifts quality control from defect detection to prevention.

-

Data Unlocks Value: Unified analytics break down silos, enabling end-to-end traceability.

-

Future-Proof Growth: Scalable AI systems adapt to new products, regulations, and technologies.

Next Steps with Assembly Line Quality

Talk to our experts about implementing compound AI system, How Industries and different departments use Agentic Workflows and Decision Intelligence to Become Decision Centric. Utilizes AI to automate and optimize IT support and operations, improving efficiency and responsiveness.